From Linear Advance:

Under default conditions, extruder axis movement is treated in the same way as the XYZ linear axes. The extruder motor moves in linear proportion to all the other motors, maintaining exactly the same acceleration profile and start/stop points. But an extruder is not a linear system, so this approach leads, most obviously, to extra material being extruded at the end of each linear movement.

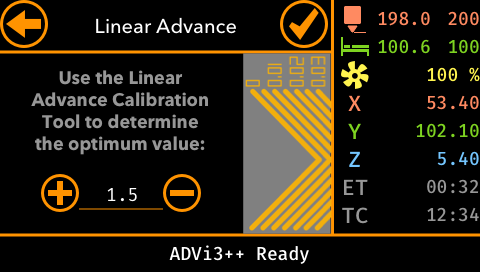

Linear Advance de-couples extrusion from the other axes to better control material pressure inside the nozzle, adapting to the printing speed. Once Linear Advance is properly tuned, bleeding edges and rough solid infill should be nearly eliminated.

Linear Advance is also known as Pressure Advance.